Jaw crusher is a primary crushing machine in the crushing plant!

The wearing parts of jaw crusher are mainly the movable jaw plate,fixed jaw plate, and toggle plate!

For the jaw plate, we can manufacture technical standard model plate,

we can also produce the non-standard model as per customers’ need, relying on high tech and

good service and superior quality, we have enjoyed high reputation in the customers!

Jaw Plate Product Description

Jaw plate is manufactured with super high manganese steel, therefore it has a service life 50~100%

longer than those made of traditional high manganese steel.

Every model of PE series jaw crushersis tested for shock, stress, strain, thermal loading,

deformation, vibration and noise under a wide range of load conditions. The special processing

techniques ensure that our jaw plate has leading performance.

Chemical Component of Jaw Plate

Material | Chemical Composition(%) | Mechanical Property | ||||

C | Si | Mn | Cr | AK/cm | HB | |

Mn13Cr2 | 1.1-1.4 | 1.7-2.2 | 12-15 | 1.7-2.2 | >140 | ≤220 |

Mn18Cr2 | 1.1-1.4 | 1.7-2.2 | 17-19 | 1.8-2.2 | >140 | ≤230 |

Jaw Plate Technical Parameters

Name | Jaw plate, swing jaw plate, fixed jaw plate, toggle plate,movable jaw,fixed jaw,jaw crusher jaw |

Material | Mn13Cr2( M1 equivalent grades),Mn18Cr2(M2 equivalent grades) |

Control | Spectrometer chemical analysis and control while producing |

Molding Process | Water-glass sand casting or lost form casting |

Melting Facility | Medium frequency electric furnace |

Heat Treatment | Anneal, quenching, tempering |

Quality Guarantee | One year against manufacturing defeat |

Testing | Hardness, flaw detector test |

Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

Application | Cement firms, coal fired power plant ,mining firms ,metallurgy ,quarry firms |

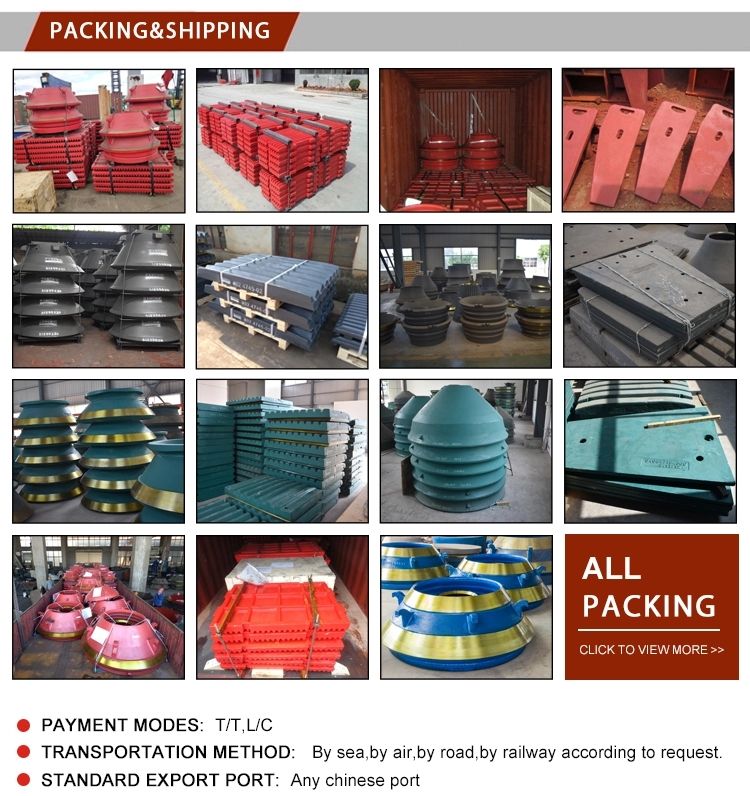

Jaw Plate Packing and Shipping