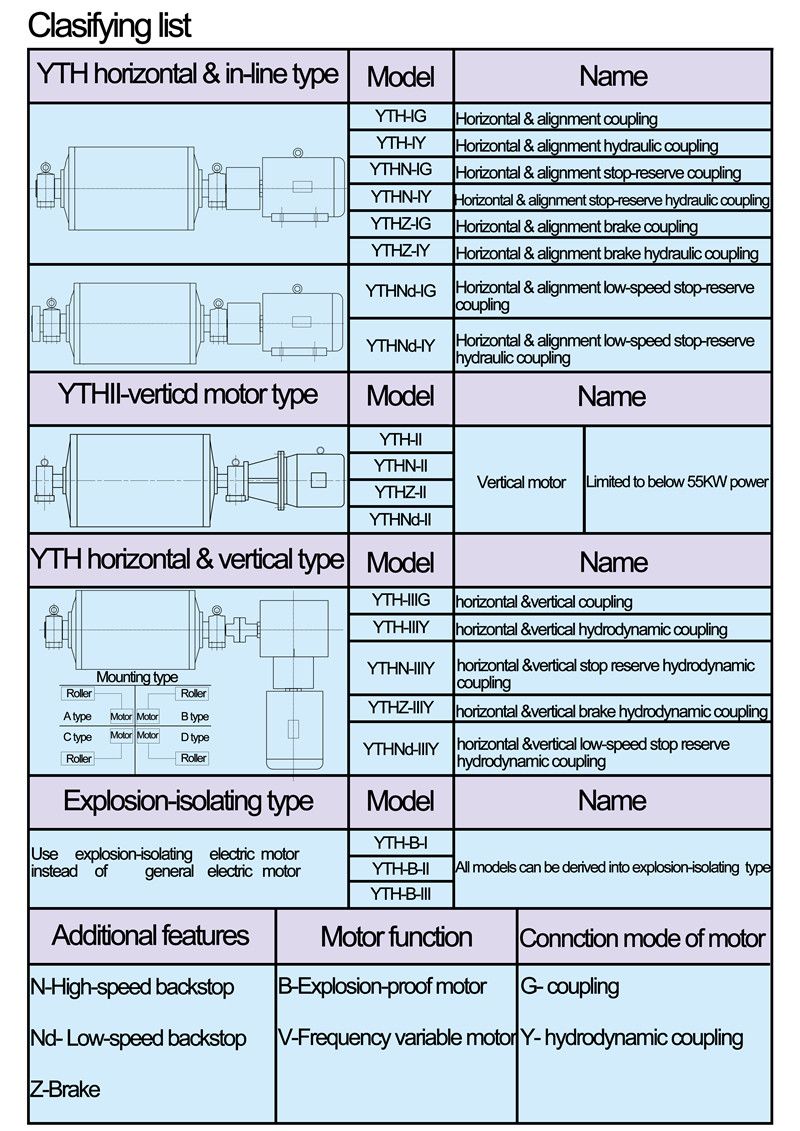

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor) is produced according to technology imported from Germany.With advantages of hardened gear surface,planetary gear drive,steady rotation,low noise,big capacity with over-load and large power range.

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor)

Product Introduction

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor) is produced according to technology imported from Germany.With advantages of hardened gear surface,planetary gear drive,steady rotation,low noise,big capacity with over-load and large power range.it can equip with hydrodynamic coupler, stop reverse unit,brake and explosion-proof electric motor and suitable to large and middle scale belt conveyer with awful environment and explosion-proof requirement.

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor) consists of three parts: drum body, drive and electric motor bracket ( II model without motor bracket). The drum body including drum shell, bracket and gear reducer. The driver includes electric motor, coupler, hydraulic coupler, stop-reverse unit and brakes etc. The bracket is designed and made by customer, it is welded by structural steel and used for erecting electric motor and the cover.

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor)

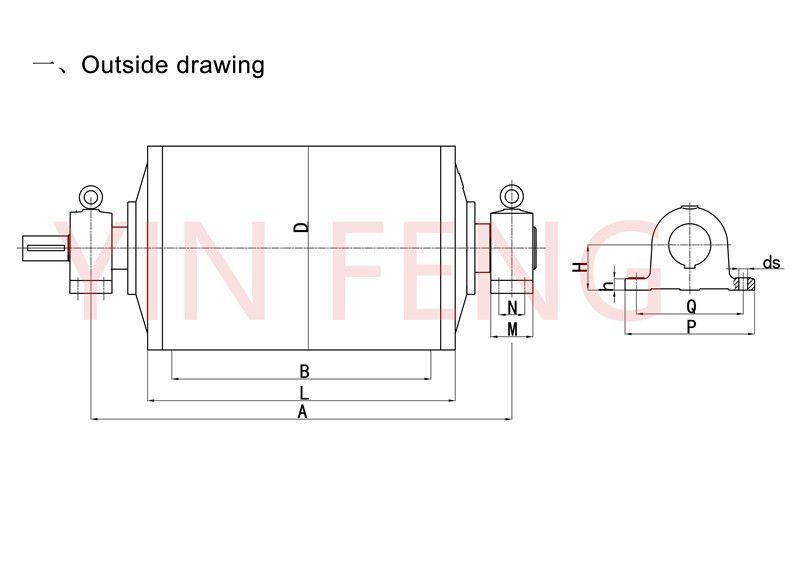

Outside Drawing

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor)

External Dimension

External dimension Unit(mm)

D | B | A | L | H | M | N | P | Q | h | ds |

Φ500

| 500 | 850 | 600 | 120 | 70 | - | 340 | 280 | 35 | Φ27 |

650 | 1000 | 750 | 120 | 90 | - | 340 | 280 | 35 | Φ27 | |

800 | 1300 | 950 | 120 | 90 | - | 340 | 280 | 35 | Φ27 | |

1000 | 1500 | 1150 | 120 | 90 | - | 340 | 280 | 35 | Φ27 | |

1200 | 1750 | 1400 | 120 | 90 | - | 340 | 280 | 35 | Φ27 | |

Φ630

| 650 | 1000 | 750 | 120 | 90 | - | 340 | 280 | 35 | Φ27 |

800 | 1300 | 950 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 | |

1000 | 1500 | 1150 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 | |

1200 | 1750 | 1400 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1400 | 2000 | 1600 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1600 | 2200 | 1800 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1800 | 2400 | 2000 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

2000 | 2600 | 2200 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

Φ800 Φ1000 | 800 | 1300 | 950 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 |

1000 | 1500 | 1150 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 | |

1200 | 1750 | 1400 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1400 | 2000 | 1600 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1600 | 2200 | 1800 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

1800 | 2400 | 2000 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

2000 | 2600 | 2200 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 |

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor)

Parameter Table

Diameter (mm) | Blet Width (mm) | Power (KW) | |||||||||

0.63 | 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | |||

Φ500 | 500 650 800 1000 1200 | 11 15 | • | • | • | • | • | • | • | • | |

18.5 22 30 37 | • | • | • | • | • | • | • | ||||

Φ630 | 650 800 1000 1200 1400 1600 1800 2000 | 11 15 | • | • | • | • | • | • | • | • | |

18.5 22 30 37 | • | • | • | • | • | • | |||||

45 55 | • | • | • | • | • | • | |||||

Φ800 | 800 1000 1200 1400 1600 1800 2000 | 11 15 | • | • | • | • | • | • | • | • | |

18.5 22 30 | • | • | • | • | • | • | |||||

30 45 55 | • | • | • | • | • | • | |||||

70 90 | • | • | • | • | • | • | |||||

110 132 | • | • | • | • | • | • | |||||

160 200 | • | • | • | • | • | ||||||

Φ1000 | 1000 1200 1400 1600 1800 2000 | 30 37 45 | • | • | • | • | • | ||||

55 75 90 | • | • | • | • | • | ||||||

110 132 | • | • | • | • | • | ||||||

160 200 | • | • | • | • | |||||||

YTH type build-out-gear-reducing motorized pulley(motorized drum/drum motor)

Feature

1.Puropose-build Design

The motorized pulley(motorized drum/drum motor) has been specifically designed for belt conveyors

2.Totally enclosed

The motor, gearbox and bearings are totally enclosed and sealed inside a steel shell;therefore they are unlikely to fail due to harmful environmental conditions such as water, dust, grit chemicals, grease, oil, etc.

3.Space saving design

Because the drive unit and the bearings are mounted inside the motorized pulley shell,it takes up much less room than a conventional drive. No need for costly extras like chains,v-belts, couplings, bearings, support structure and special guarding.

4.Safety

The motorized pulley(motorized drum/drum motor) is probably one of the safest drives available because the motoris completely enclosed and the external shafts are always stationary. The only moving external parts are the motorized pulley shell and bearing housings.

5.Low purchasing and installation cost

The motorized pulley(motorized drum/drum motor) is quite often less expensive than exposed drives because it has fewer parts.Therefore less conveyor design and parts purchasing costs. It is also much quicker and easier to install-certainly less than a quarter of the time taken to fit an exposed system.

6.Low maintenance cost

The end user also benefits from the motorized pulley(motorized drum/drum motor), because it requires no maintenance other than the recommended oil change every 10,000 hours and oil seal change every 30,000 hours. In other words almost 5 years between oil changes based on 8-hour/day working week. Synthetic oil can be specified to extend the service range up to 30,000 hours.

7.Efficiency

The XINGLI motorized pulley usually has a much higher efficiency from electrical motor to shell(pulley face) than conventional drives, because it has fewer frictional losses, and therefore efficiencies of up to 94% can be achieved.

8.Fewer parts

A motorized pulley consists of the motorized pulley and two fixing brackets!

Exposed drives can require up to eight or more separate components,

most of which have to be purchased from different supplier or custom manufactured.

9.Low noise

Thanks to the totally sealed enclosure and high quality gears, the motorized pulley(motorized drum/drum motor) runs almost at an important fact in todays modern factory environments.

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor) Photos

YTH type build-out-gear-reducing motorized pulley (motorized drum/drum motor) Packaging