Choosing the right slurry pump for your application can be a daunting task. Slurry pumps can be found in almost every industry and play a vital role in many processes. The four key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump arrangement, and proper slurry pump power selection.

The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges can contain large amounts of unforeseen solids that will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm housing, the abrasive (and sometimes corrosive) nature of the slurry can quickly wear down the worm housing and break the tolerances. This in turn causes the pump to lose its suction power. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

Selecting the right material for a slurry pump is another critical process in determining the right pump for handling slurries. If the slurry is highly abrasive with a neutral pH, the best construction material is Hi-Chrome, a metallurgy with the highest Brinell hardness that can withstand the abrasive nature of the slurry. On the other hand, if the slurry is not only abrasive, but also has a low pH value, then a duplex stainless steel construction is preferred.

It is important to select the ideal seal based on the abrasiveness of the slurry. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. This keeps the seal face cool at all times without causing the slurry to overheat the seal and crack the surface.

Determining the right slurry pump size and power requirements for your application is critical. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to operate at a slow enough speed to extend the life of the slurry pump.

If you aren't sure what kind of pump to use in your slurry application, check out our WEB or contact us! Our experienced engineers will gladly assist your business.

Просмотреть больше

Просмотреть больше

Просмотреть больше

Просмотреть больше

Вертикальный центробежный насос для тяжелых шламов серии YZS

Просмотреть больше

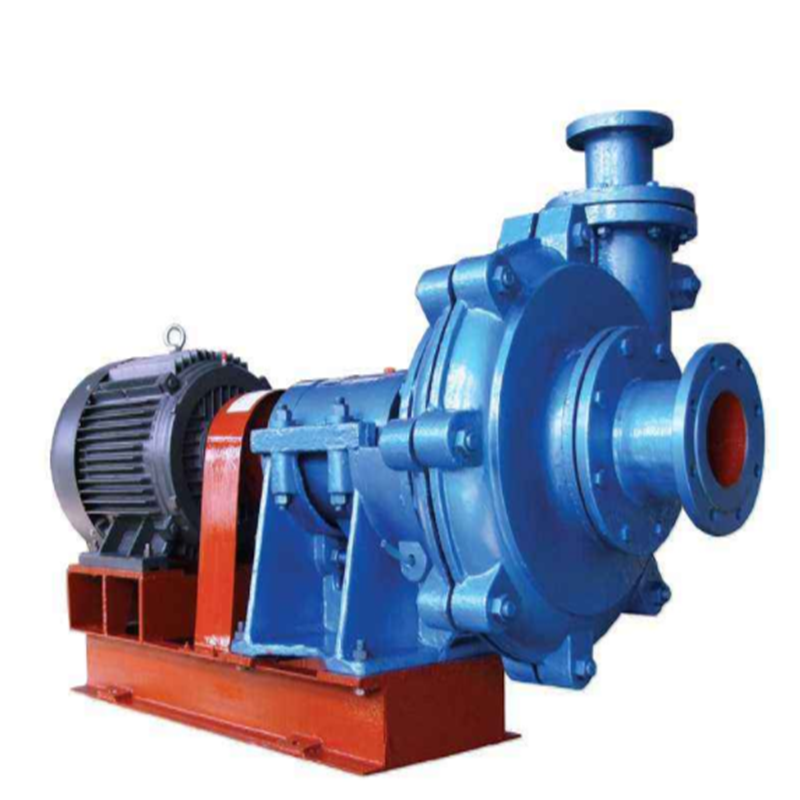

Горизонтальный центробежный шламовый насос

Просмотреть больше Просмотреть больше

Просмотреть больше

DCY Конический/цилиндрический зубчатый редуктор с закаленной поверхностью зуба (коробка передач)

Просмотреть больше

TDY75 Type Oil-cooled Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

Тип YTH Моторизованный шкив с редуктором (моторизованный барабан/барабанный двигатель)

Просмотреть больше

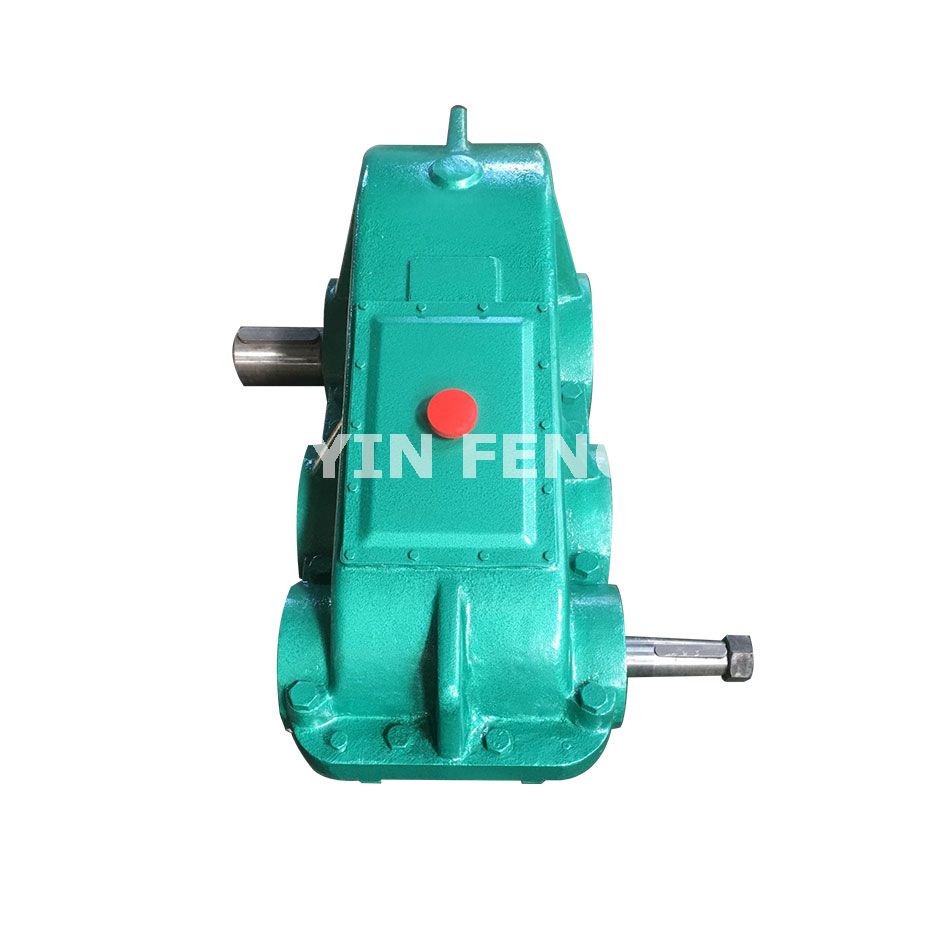

Редуктор/коробка передач ZQ/JZQgear

Просмотреть больше

ZSY Hardened cylindrical Gear Reducer/Conveyor Gearbox

Просмотреть больше

YZ Type Oil-cooled/Oil-steeped Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

YZW Type Build-out Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше