As a Conveyor Belt Puller Manufacturer, share with you. During the use of the belt conveyor, the running status of the deviation switch is directly related to the life of equipment and personnel in the production process. Therefore, how to make the protective device of the belt conveyor to play a protective role in the production operation stably and reliably has very important practical significance. The belt conveyor is easy to run off and slip during operation is a common problem in the user's use process, these problems are easy to cause the conveyor belt to break and other failures. The following editor will explain the selection and installation of the deviation switch, and I hope it will help you.

Conveyor Belt Puller

Conveyor Belt Puller's deflection switch is a protection device used to detect the degree of deflection of the conveyor belt during the operation of the belt conveyor and give an alarm. It is also used to automatically trigger an emergency stop when the belt is seriously deflecting. The deflection switch is fixedly installed on the brackets on both sides of the belt conveyor at a certain interval. The roller part of the deflection switch is deflected after being squeezed by the edge of the conveyor belt that deviates. When the roller is deflected to a certain angle, the switch contact action is triggered. . It can detect the different deviation degree of the belt and provide more information for the control system. Preference is given to products with action memory and action status indication on the switch body. Because the belt conveyor is running dynamically, with this function, it is easy to determine the specific position of the belt deviation, analyze the cause of deviation, and also facilitate the commissioning and maintenance of the equipment. The mounting bracket of the deviation switch should be made into a structure that can adjust the position of the deviation switch along the side of the belt. This is to adjust the range of allowed deviation according to the actual situation on the spot.

The application of belt conveyor-belt conveyor in injection molding auxiliary machine: The belt conveyor series is widely used in the extrusion product transportation of injection molding machinery and plastic equipment. It is a kind of workpiece product suitable for various types of PVC powder extrusion molding. Placed on the conveying equipment for conveying sorting, assembly, inspection and other functions.

Belt conveyor equipped with different conveying auxiliary machines can produce and convey various types of PVC plastic pipes, profiles, plates, sheets, rods and pellets and other finished products or leftover injection molding scraps.

Our company also has Motorized Pulley for sale, please contact us.

Просмотреть больше

Просмотреть больше

Просмотреть больше

Просмотреть больше

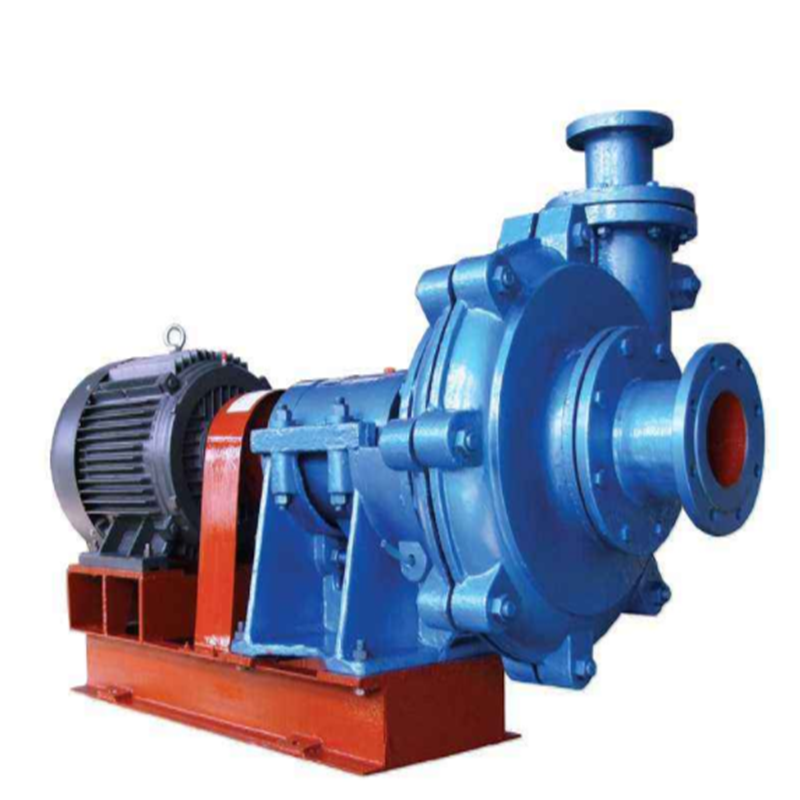

Вертикальный центробежный насос для тяжелых шламов серии YZS

Просмотреть больше

Горизонтальный центробежный шламовый насос

Просмотреть больше Просмотреть больше

Просмотреть больше

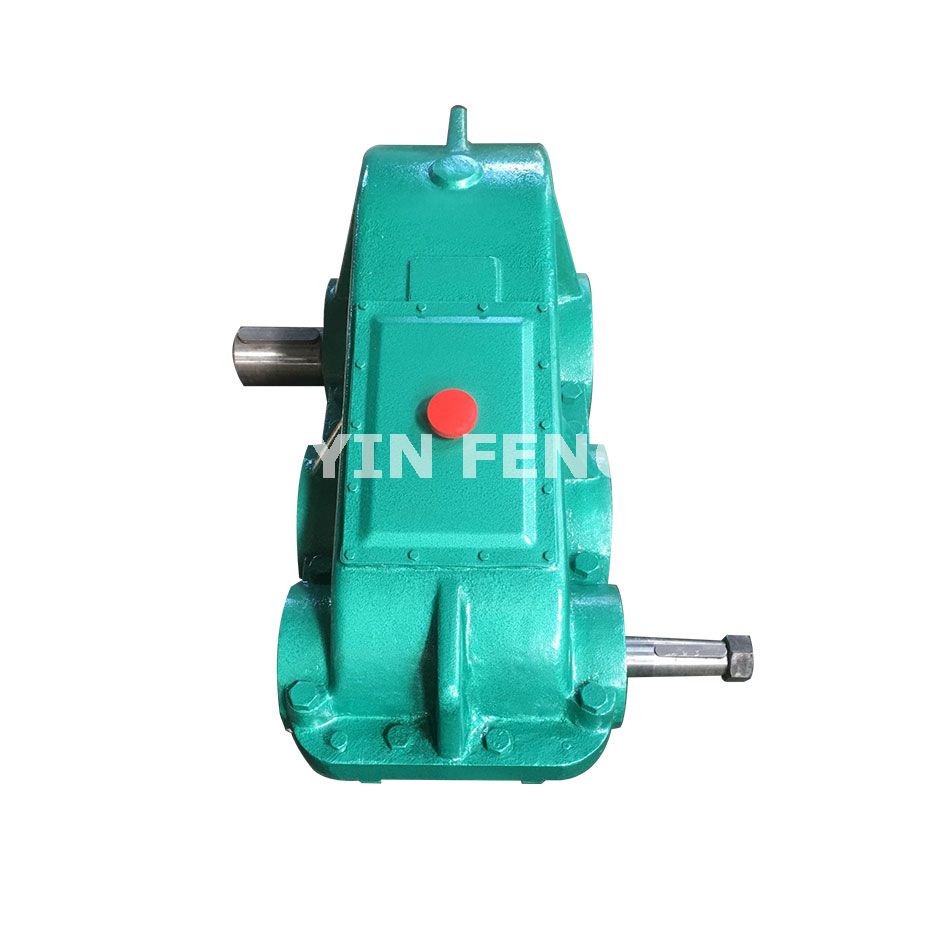

DCY Конический/цилиндрический зубчатый редуктор с закаленной поверхностью зуба (коробка передач)

Просмотреть больше

TDY75 Type Oil-cooled Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

Тип YTH Моторизованный шкив с редуктором (моторизованный барабан/барабанный двигатель)

Просмотреть больше

Редуктор/коробка передач ZQ/JZQgear

Просмотреть больше

ZSY Hardened cylindrical Gear Reducer/Conveyor Gearbox

Просмотреть больше

YZ Type Oil-cooled/Oil-steeped Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

YZW Type Build-out Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше