As a Submersible Pump Supplier, I would like to share with you the following

reasons for the unstable flow rate of the slurry pump:

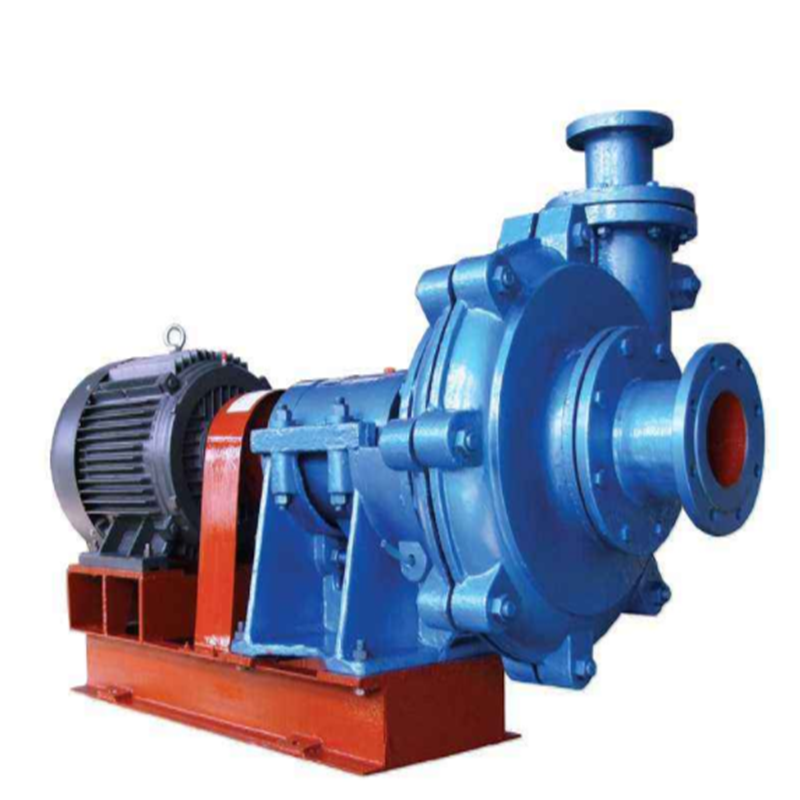

Submersible Pump

1. The suction pipe or bottom valve leaks, or the water inlet is blocked, which is a common cause of insufficient flow. It is necessary to check the air leakage source of the suction pipe and the bottom valve and block it in time, or clean the silt or blockage at the water inlet.

2. The voltage is too low and the speed of the slurry pump is reduced, resulting in insufficient flow of the slurry pump. At this time, the power supply voltage should be checked and adjusted in time.

3. If there is air leakage in the pipeline or there is air in the pump body, the air in the pipeline can be discharged in time.

4. Severe wear of the seal ring or impeller will also cause the slurry pump to flow instability. The severely worn seal ring and impeller should be checked and replaced in time.

5. The depth of the bottom valve is not enough to cause air to enter when pumping. The depth of the bottom valve should be adjusted according to the suction stroke of the slurry pump.

6. If the slurry pump works normally within a period of time after starting, but the current gradually drops and the flow is obviously insufficient, this problem still occurs after restarting the normal operation for a period of time, mostly due to the accumulation of slurry or other debris in the suction pipe. Cavitation occurs in the slurry pump. When it is more serious, there will be loud noises in the slurry pump and obvious vibration of the pump head. At this time, the front pool and suction pipe should be thoroughly cleaned, and the length below the elbow should be reduced, or a stirring device should be added to reduce The slurry settles.

There is air in the slurry pump body or the gas in the water inlet pipe, or the bottom valve is not closed tightly, and the water diversion is not full, the vacuum pump packing is seriously leaking, and the gate valve or flap door is not closed tightly. Remedy: First press the water up, then fill the pump body with water, and then turn it on. At the same time, check whether the check valve is tight and whether there is air leakage in the pipeline and joints. If air leakage is found, apply lubricating oil or mixed paint to the joint after disassembly, and tighten the screws. Check the oil seal ring of the water pump shaft and replace it with a new one if it is severely worn. Water or air leakage in the pipeline. The nut may not be tightened tightly during installation.

If the leakage is not serious, apply cement or cement slurry mixed with asphalt oil on the leaking or leaking place. Temporary repairs can be coated with wet mud or soft soap. If there is water leakage at the joint, you can use a wrench to tighten the nut. If the water leakage is serious, you must re-disassemble and replace the cracked pipe; reduce the head and press the nozzle of the pump into the water 0.5m.

Our company also has Submersible Pump on sale, welcome to contact us.

Просмотреть больше

Просмотреть больше

Просмотреть больше

Просмотреть больше

Вертикальный центробежный насос для тяжелых шламов серии YZS

Просмотреть больше

Горизонтальный центробежный шламовый насос

Просмотреть больше Просмотреть больше

Просмотреть больше

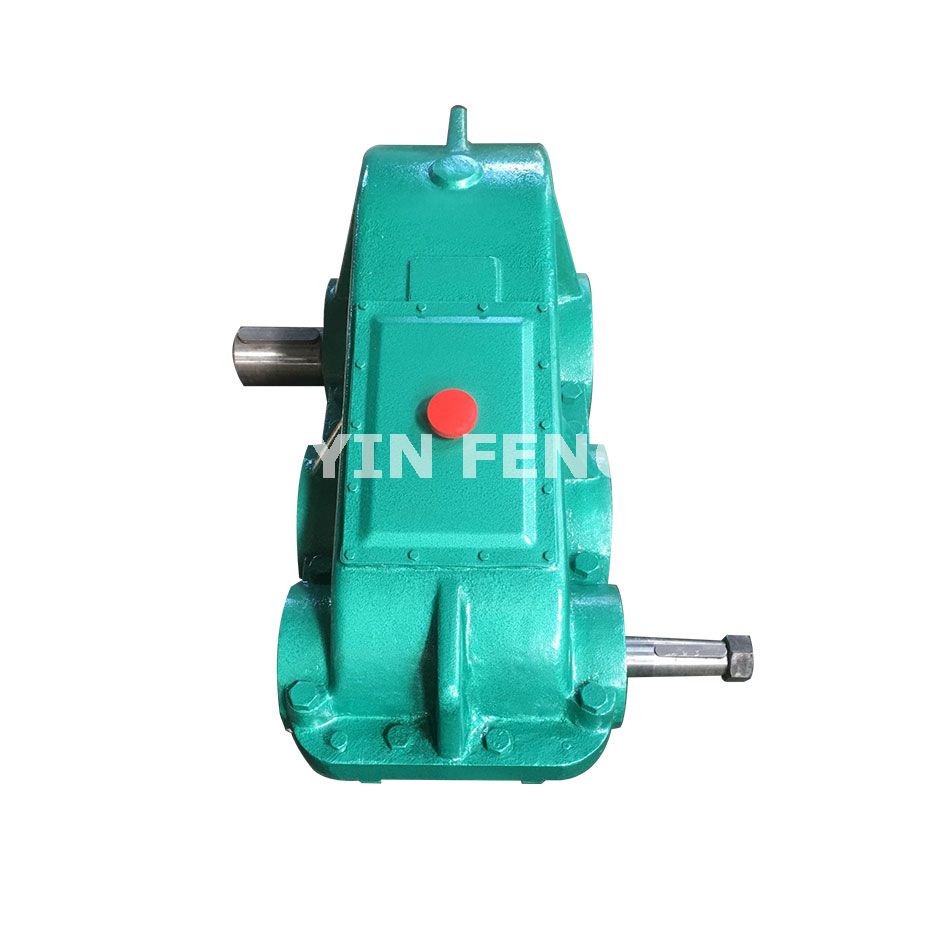

DCY Конический/цилиндрический зубчатый редуктор с закаленной поверхностью зуба (коробка передач)

Просмотреть больше

TDY75 Type Oil-cooled Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

Тип YTH Моторизованный шкив с редуктором (моторизованный барабан/барабанный двигатель)

Просмотреть больше

Редуктор/коробка передач ZQ/JZQgear

Просмотреть больше

ZSY Hardened cylindrical Gear Reducer/Conveyor Gearbox

Просмотреть больше

YZ Type Oil-cooled/Oil-steeped Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

YZW Type Build-out Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше