As a Motorized Drum Manufacturer, share with you. Before the selection of

electric drums, the working conditions, environment and use requirements must be

determined by standards, and then the types are selected according to the

needs:

Motorized Pulley

1. Material and surface treatment of cylinder tube: Determine the material and surface treatment method of the electric drum according to the use environment.

2. The length of the electric drum: the length of the electric drum should be selected according to the width of the conveyor and the goods to be transported. In general, the method of "transporting material +50mm" is used to select.

3. Wall thickness and shaft diameter selection: the weight of the conveyed material is evenly distributed to the contacting rollers, and the required load of each branch is calculated, so as to determine the shaft diameter and wall thickness of the rollers.

4. Choose the installation method: According to the specific requirements of the electric roller conveyor, choose the installation and fixing method. The main installation and fixing methods are back-up cutting shaft, external thread shaft, spring press-in type, full flat tenon type, internal thread shaft type, Pin hole type.

The material, length, thickness, etc. of the electric drum are very different. The electric drum is customized and processed according to customer requirements.

5. Determination of the power of the electric drum

(1) According to the following formula, the motor power of the electric drum is required. (According to the actual application of some continuous conveyor machinery at home and abroad, it can be seen that its power calculation results for large and micro conveyors are too small. The user can choose the safety factor by himself, and it is recommended that Pact=P÷0.8)

Power calculations have recommended formulas in various mechanical manuals, but the methods are not the same and the calculation results may be slightly different.

Motorized Pulley selection considerations

The electric power calculated according to the above formula needs to be corrected in the following cases.

1. The electric drum works continuously for 8 hours a day, and the motor power needs to be increased by one gear.

2. For drum-coated electric drums, the motor power should be increased by one gear.

3. If the electric drum is started frequently, the motor power should be increased by one gear.

The electric drum should be installed horizontally, and the maximum inclination angle should not exceed 15°.

3. The user should replace the lubricant in strict accordance with the type of lubricant specified in the instruction manual.

4. When restricting rotation in one direction, electric drums with mechanical backstops should be used.

5. When it is required to stop immediately after power failure, electric drums with electromagnetic brakes should be used.

Our company also has Conveyor Drum for sale, please contact us.

Просмотреть больше

Просмотреть больше

Просмотреть больше

Просмотреть больше

Вертикальный центробежный насос для тяжелых шламов серии YZS

Просмотреть больше

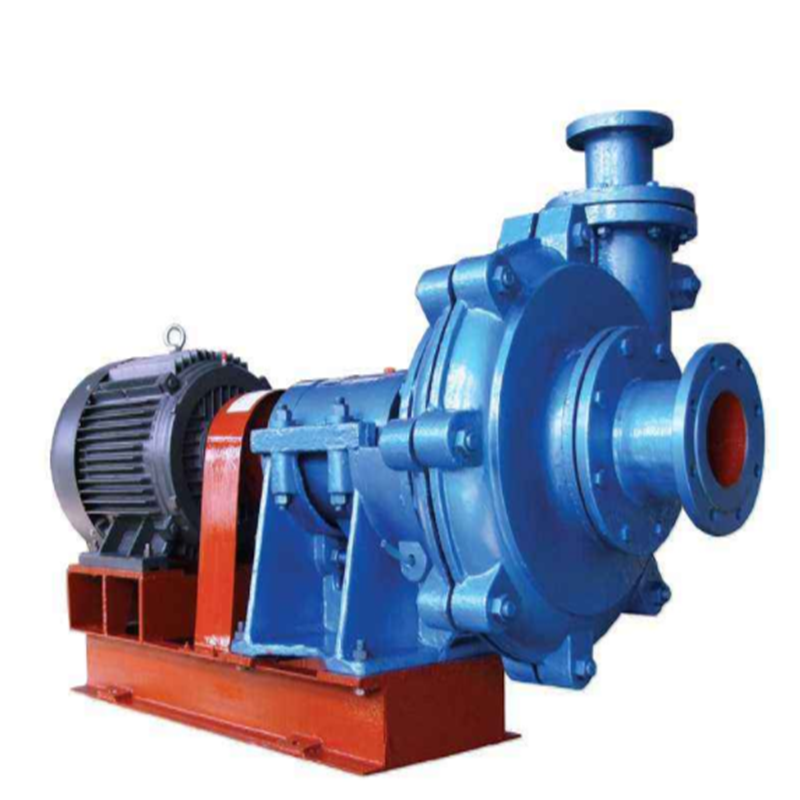

Горизонтальный центробежный шламовый насос

Просмотреть больше Просмотреть больше

Просмотреть больше

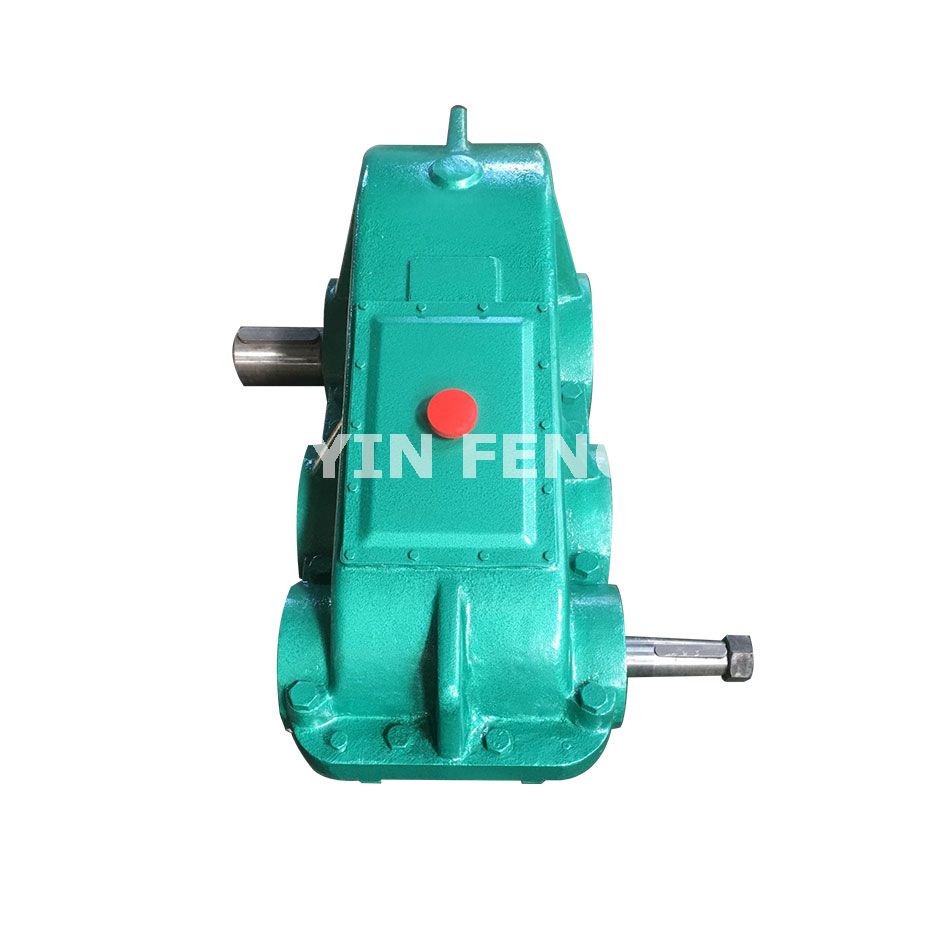

DCY Конический/цилиндрический зубчатый редуктор с закаленной поверхностью зуба (коробка передач)

Просмотреть больше

TDY75 Type Oil-cooled Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

Тип YTH Моторизованный шкив с редуктором (моторизованный барабан/барабанный двигатель)

Просмотреть больше

Редуктор/коробка передач ZQ/JZQgear

Просмотреть больше

ZSY Hardened cylindrical Gear Reducer/Conveyor Gearbox

Просмотреть больше

YZ Type Oil-cooled/Oil-steeped Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше

YZW Type Build-out Motorized Pulley (Motorized Drum/Drum Motor)

Просмотреть больше