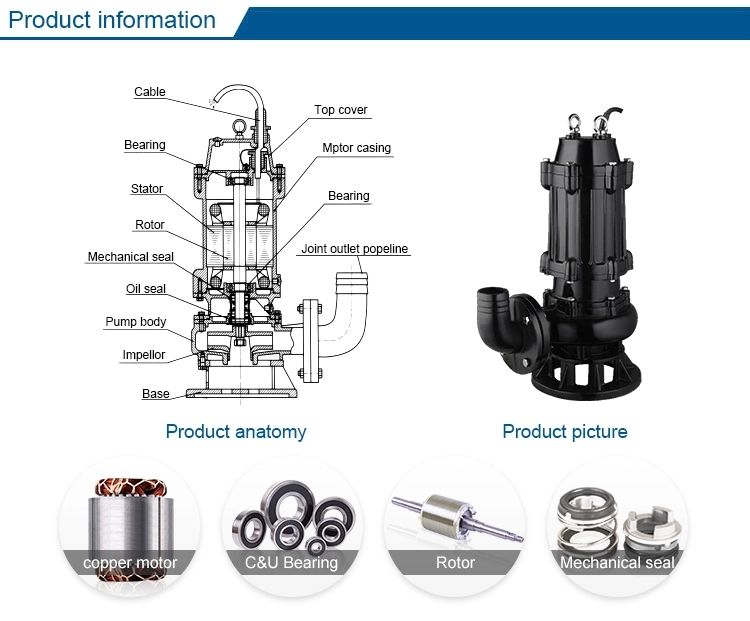

The submersible sewage pump (waste dirty water pump) consists of three parts: motor, pump and seal.The motor is located at the upper part of the electric pump, which is a three-phase asynchronous motor. The alloy double-end mechanical seal is used between the pump and the motor.

The submersible sewage pump (waste dirty water pump) consists of three parts: motor, pump and seal.The motor is located at the upper part of the electric pump, which is a three-phase asynchronous motor. The alloy double-end mechanical seal is used between the pump and the motor.This model has features such as energy-saving, anti-winding, non-clogging, automatic installation and automatic control.

The submersible sewage pump (waste dirty water pump) uses special structure impeller and new mechanical seals to make it more efficient in delivering sewage with solid particles and long fibers. Compared with traditional impellers, the new ones (spiral-flow type or double-leaf type) have an excellent delivery capacity, which improves the pump performance. It runs more smoothly without any vibration.

The submersible sewage pump (waste dirty water pump) main use: widely used in industry, agriculture, mining, civil construction, municipal environmental protection and other places, it is the ideal equipment for pumping mud, mortar, domestic wastewater, sewage feces and urine, and containing short fiber, paper, sand and other solid particles and rural drainage irrigation river pond silt.

The submersible sewage pump (waste dirty water pump) can be customized with 304/316 stainless steel type, high temperature resistent type and cutting impeller type.

· Sewage discharge of residential community

· Sewage system of municipal projects

· Sewage system of factories and mine enterprises

· Sewage discharge of public facilities

· Other sewage system

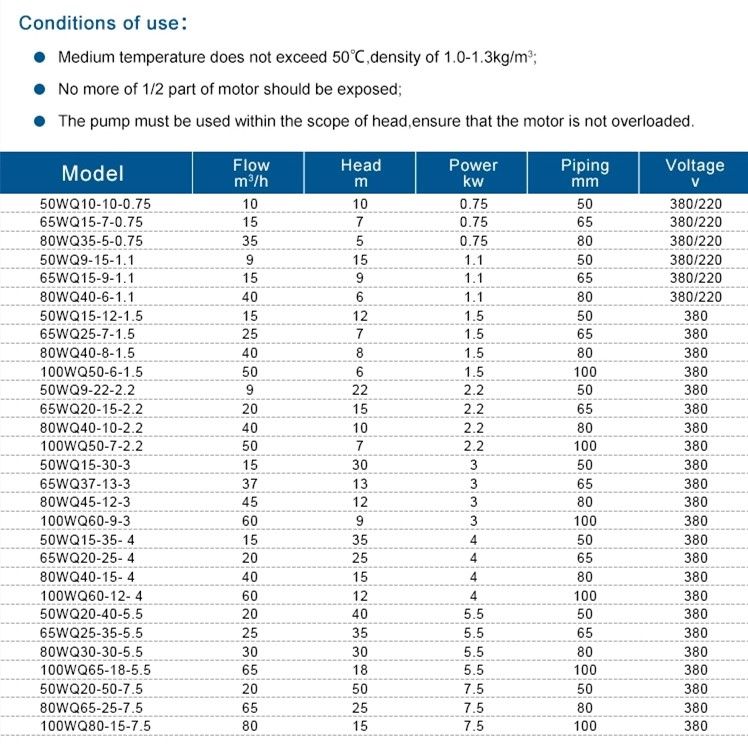

Proper medium: liquids with chemical property similar to pure water should be non-corrosive. Solid size should be no larger than 30% of the pump suction diameter. Fiber length should not be over 2.5 times of the pump suction diameter. When the medium density is more than 1.05, the motor power should be increased accordingly to prevent the motor from overload operation.

Check whether pump fasteners are loosen and whether the pump body runner is blocked by foreign matters before installation to avoid damage of impeller and pump body in running.

Supporters for the outlet pipe should be installed separately so that the weight will not be added to the pump so as to prevent it from deformation.

The pump base for both movable and fixed installation must be leveled by a level. After the base is ready, install the pump on the base and then use a level to check horizontal and vertical situation between the pump and motor shaft. Use the iron shim to change the height of the base if the pump is out of level. Then grout the base and anchor bolt holes by pouring the concrete into the grout hole.

The levelness of the coupling device should be calibrated by a level when coupling installation is adopted. Horizontal level tolerance should not exceed 0.1mm/m. Use the measure gage to calibrate parallelism of two coupling rods to ensure the parallelism tolerance will not exceed 0.2mm/m.

Tighten the anchor bolt to make sure there is no looseness between the anchor bolt and concrete in case of bad influence on pump performance when starting.

For easy maintenance and safe use, install a regulating valve on the outlet pipe and a pressure gauge near the outlet to guarantee the normal operation within the rated performance range, which lengthens the lifetime of pumps.

Rotate the impeller from the suction side after installation. Disassemble the pump and find out the reasons if there is friction or stuck pump.

The pump installation can be divided into three types, movable type, fixed type and coupling type.