DCY reducer is a rigid gear reducer of threw-stage driving.It as the power equipment of belt conveyorare ,is widely used in metallurgy、mining、lifting、transportation、Cement、construction、chemical、building、materials、light industry、petroleum、printing、dyeing and textile etc.

DCY Hardened Tooth Surface Bevel/Cylindrical Gear Reducer(Gearbox) Product Description

DCY type hardened bevel/cylindrical reducer with small size, light weight, long life, high load carrying capacity. It produced by national standards JB/T8853-2001.The input and output of a gear transmission mechanism of vertical layout of the state. Transmission gear is made of high quality alloy steel, carburizing quenching, grinding and other processes, precision grade 6, hardness is HRC60 (58 ~ 62). Applied to a variety of belt conveyors and transport machinery, can also be used in metallurgy, mining, chemical, coal, building materials, petroleum and other general machinery.

The charactic of DCY hardened tooth surface bevel/cylindrical gear reducer(gearbox)

1.The gear is made of high strength low carbon alloy steel through carburization and quenching.The hardness of tooth surface may reach to HRC58-62. All gear adapts NC tooth grinding process, high in accuracy and good in contact performance

2.High in transmission efficiency:

single stage, more than 96.5%; double-stage, more than 93%; three-stage, more 90%;

3.Smooth and stable in run, low noise;

4.Compact, light, long life, high bearing capacity;

5.Easy to disassemble, inspect and assemble.

DBY hardened tooth surface bevel/cylindrical gear reducer(gearbox) Working Condition:

1. High-speed shaft speed not more than 1500 rev / min

2. Gear circumferential velocity not more than 20 m / sec.

3. The working environment temperature -40 ~ 45 ℃. If less than 0 ℃, before the start of oil should be preheated to above 0 ℃, the reducer can be used in both directions running.

Hardened tooth surface bevel/cylindrical gear reducer(gearbox) Type

1. DBY reducer is a rigid gear reducer of two-stage driving. DCY reducer is a rigid gear reducer of threw-stage driving, with first stage driving by Gleason spiral bevel gear and second and third stage driving by involute cylindrical spiral gear.

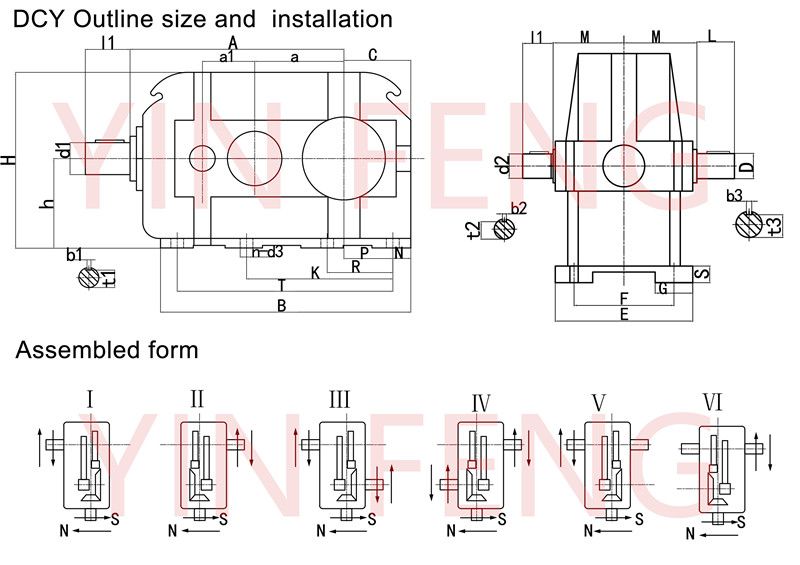

2.The reducer may fall into six types of assembly:. I, II, III ,IV,V,VI in respect of its input shaft, or into two types, S and N, in respect of its rotary direction of output shaft. (Facing to output shaft)

DCY hardened tooth surface bevel/cylindrical gear reducer(gearbox)

DBY hardened tooth surface bevel/cylindrical gear reducer(gearbox)

Outside Drawing and Assembled Form Unit(mm)

Center Distance ( a) | a1 | d1 | I1 | d2 | I2 | D | L | A | B | C | E | F | G | S | h | H | M |

160 | 112 | 25 | 60 | 32 | 80 | 70 | 140 | 510 | 555 | 190 | 250 | 210 | 65 | 35 | 180 | 423 | 145 |

180 | 125 | 30 | 80 | 38 | 80 | 170 | 575 | 625 | 215 | 270 | 230 | 70 | 35 | 200 | 468 | 160 | |

200 | 140 | 35 | 42 |

110 | 90 | 640 | 685 | 240 | 300 | 250 | 75 | 40 | 225 | 520 | 175 | ||

224 | 160 | 40 |

110 | 48 | 100 |

210 | 725 | 775 | 260 | 320 | 270 | 80 | 45 | 250 | 570 | 190 | |

250 | 180 | 42 | 50 | 110 | 815 | 860 | 290 | 370 | 310 | 90 | 50 | 280 | 626 | 210 | |||

280 | 200 | 50 | 55 | 120 | 905 | 970 | 325 | 400 | 340 | 100 | 55 | 315 | 702 | 230 | |||

315 | 224 | 55 | 65 | 140 | 140 | 250 | 1020 | 1085 | 355 | 450 | 380 | 110 | 60 | 355 | 809 | 260 | |

355 | 250 | 60 |

140 | 75 | 160 | 300 | 1140 | 1220 | 390 | 480 | 410 | 120 | 65 | 400 | 900 | 285 | |

400 | 280 | 65 | 85 | 170 | 170 | 1275 | 1355 | 440 | 530 | 460 | 130 | 70 | 450 | 970 | 305 | ||

450 | 315 | 75 | 95 | 190 | 350 | 1425 | 1520 | 490 | 600 | 510 | 140 | 80 | 500 | 1065 | 345 | ||

500 | 355 | 90 | 170 | 100 | 210 | 220 | 1585 | 1692 | 570 | 650 | 560 | 150 | 90 | 560 | 1208 | 435 | |

560 | 400 | 100 |

210 | 110 | 250 | 410 | 1775 | 1895 | 610 | 750 | 640 | 160 | 100 | 630 | 1325 | 475 | |

630 | 450 | 110 | 130 | 250 | 300 | 470 | 1995 | 2145 | 675 | 800 | 690 | 170 | 110 | 710 | 1460 | 525 | |

710 | 500 | 120 | 150 | 340 | 550 | 2235 | 2400 | 760 | 900 | 770 | 190 | 125 | 800 | 1665 | 570 | ||

800 | 560 | 130 | 250 | 160 | 300 | 400 | 650 | 2505 | 2700 | 840 | 1000 | 870 | 200 | 140 | 900 | 1870 | 625 |

Center Distance(a) | n-d3 | N | P | R | K | T | b1 | t1 | b2 | t2 | b3 | t3 | Weight(kg) |

160 | 6-18 | 30 | 115 | 210 |

- | 495 | 8 | 28 | 10 | 35 | 20 | 74.5 | 200 |

180 | 135 | 240 | 565 | 33 | 41 | 22 | 85 | 255 | |||||

200 | 6-23 | 35 | 145 | 255 | 615 | 10 | 38 | 12 | 45 | 25 | 95 | 325 | |

224 | 165 | 290 | 705 | 12 | 43 | 14 | 51.5 | 28 | 106 | 453 | |||

250 | 6-27 | 40 | 180 | 315 | 780 | 45 | 53.5 | 116 | 586 | ||||

280 | 45 | 200 | 355 | 880 | 14 | 53.5 | 16 | 59 | 32 | 127 | 837 | ||

315 |

6-32 | 50 | 220 | 405 | 655 | 985 | 16 | 59 | 18 | 69 | 36 | 148 | 1100 |

355 | 55 | 245 | 450 | 740 | 1110 | 18 | 64 | 20 | 79.5 | 40 | 169 | 1550 | |

400 | 280 | 510 | 840 | 1245 | 69 | 22 | 90 | 179 | 1967 | ||||

450 | 8-39 | 60 | 315 | 575 | 940 | 1400 | 20 | 79.5 | 25 | 100 | 45 | 200 | 2675 |

500 | 70 | 350 | 645 | 1050 | 1550 | 25 | 95 | 28 | 106 | 50 | 231 | 4340 | |

560 | 8-45 | 80 | 390 | 715 | 1165 | 1735 | 28 | 106 | 116 | 56 | 262 | 5320 | |

630 | 445 | 800 | 1305 | 1985 | 116 | 32 | 137 | 70 | 314 | 7170 | |||

710 | 90 | 500 | 900 | 1490 | 2220 | 32 | 127 | 36 | 158 | 80 | 355 | 9600 | |

800 | 560 | 1100 | 1680 | 2520 | 137 | 40 | 169 | 90 | 417 | 13340 |

Model | Transmission Ratio | ||||||||||

DBY160-800 | 16 | 18 | 20 | 22.4 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 |

DCY hardened tooth surface bevel/cylindrical gear reducer(gearbox) Display

DCY hardened tooth surface bevel/cylindrical gear reducer(gearbox) Packaging