ZDY single-stage cylindrical gear speed reducer, ZLY double-stage cylindrical gear speed reducer,ZSY three-stage cylindrical gear speed reducer.It as the power equipment of belt conveyorare ,is widely used in metallurgy、mining、lifting、transportation、Cement、construction、chemical、building、materials、light industry、petroleum、printing、dyeing and textile etc.

ZLY Hardened cylindrical Gear Reducer/Gearbox Product Description

ZSY/ZLY/ZDY Cylindrical gear reducer gear carburizing, quenching, grinding, high bearing capacity, low noise; mainly used for belt conveyor and various kinds of transport machinery, can also be used to drive other general machinery. It has the advantages of high bearing capability, long service life, small volume, high efficiency, light weight, for the input shaft and the output shaft is vertically arranged in the driving device.

The field of cylindrical gear reducer is widely used in metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment etc.

ZLY Hardened cylindrical Gear Reducer/Gearbox Characteristics:

1. Small size, light weight, high accuracy, large carrying capacity, high efficiency, long service life, high reliability, transmission smoothly, low noise.

2.All the gear are made of high quality alloy steel, processe by carburizing and quenching, and the hardness of tooth surface is reach up to hrc54 - 62.CNC grinding technology is adopted for all gears, with high precision and good contact performance.

3. high transmission efficiency: single stage over 96.5%; double stage over 93%; three stage over 90%.

4.stable operation and low noise;compact structure, light weight, long service life and high bearing capacity.

5.Optimized design for the center distance and nominal transmission ratio. Have good interchangeability for the main parts and components.

6.Use oil samp to lubricate, natural cooling.

7.easy to disassemble, check and assemble.

ZLY Hardened cylindrical Gear Reducer/Gearbox Application:

1.The input speed is generally ≤ 1500 r/min.

2. It can be widely used in metallurgical, mining, chemical, construction, lifting, transportation, textiles, paper making, instruments, plastics, rubber, energy and other industrial field.

3. The circumferential speed of gear drive is no more than 20 m / s.

4.The working temperature is - 40~50 ℃, if less than 0℃. Lubricating oil should be preheated more than 0 ℃ before start running. This gear reducer can run reversible.

Hardened cylindrical Gear Reducer/Gearbox Types

ZDY single-stage cylindrical gear speed reducer, ZLY double-stage cylindrical gear speed reducer,

ZSY three-stage cylindrical gear speed reducer.

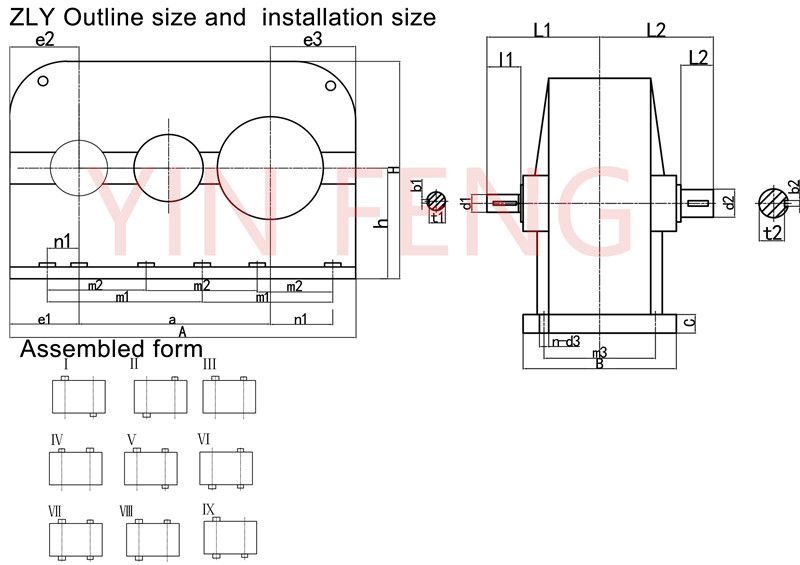

ZLY Hardened cylindrical Gear Reducer/Gearbox Outline Size and Installation size

ZLY Hardened cylindrical Gear Reducer/Gearbox

Outside Drawing and Assembled Form Unit(mm)

Model | A | B | H ≈ | a | Transmission Ratio :i=12.5~20 | d2 (m6) | I2 | L2 | b2 | t2 | ||||||||||

d1 (m6) | I1 | L1 | b1 | t1 | d1 (m6) | I1 | L1 | b1 | t1 | |||||||||||

112 | 385 | 215 | 265 | 192 | 24 | 36 | 141 | 8 | 27 | 22 | 36 | 141 | 6 | 24.5 | 48 | 82 | 192 | 14 | 51.5 | |

125 | 425 | 235 | 309 | 215 | 28 | 42 | 157 | 8 | 31 | 24 | 36 | 151 | 8 | 27 | 55 | 82 | 207 | 16 | 59 | |

140 | 475 | 245 | 335 | 240 | 32 | 58 | 185 | 10 | 35 | 28 | 42 | 167 | 8 | 31 | 65 | 105 | 230 | 18 | 69 | |

160 | 540 | 290 | 375 | 272 | 38 | 58 | 198 | 10 | 41 | 32 | 58 | 198 | 10 | 35 | 75 | 105 | 245 | 20 | 79.5 | |

180 | 600 | 320 | 435 | 305 | 42 | 82 | 232 | 12 | 45 | 32 | 58 | 208 | 10 | 35 | 85 | 130 | 285 | 22 | 90 | |

200 | 665 | 355 | 489 | 340 | 48 | 82 | 247 | 14 | 51.5 | 38 | 58 | 223 | 10 | 41 | 95 | 130 | 300 | 25 | 100 | |

224 | 755 | 390 | 515 | 384 | 48 | 82 | 267 | 14 | 51.5 | 42 | 82 | 267 | 12 | 45 | 100 | 165 | 355 | 28 | 106 | |

250 | 830 | 450 | 594 | 430 | 60 | 105 | 315 | 18 | 64 | 48 | 82 | 292 | 14 | 51.5 | 110 | 165 | 380 | 28 | 116 | |

280 | 920 | 500 | 670 | 480 | 65 | 105 | 340 | 18 | 69 | 55 | 82 | 317 | 16 | 59 | 130 | 200 | 440 | 32 | 137 | |

315 | 1030 | 570 | 780 | 539 | 75 | 105 | 365 | 20 | 79.5 | 60 | 105 | 365 | 18 | 64 | 140 | 200 | 470 | 36 | 148 | |

355 | 1150 | 600 | 870 | 605 | 85 | 130 | 410 | 22 | 90 | 70 | 105 | 385 | 20 | 74.5 | 170 | 240 | 530 | 40 | 179 | |

400 | 1280 | 690 | 968 | 680 | 90 | 130 | 440 | 25 | 95 | 80 | 130 | 440 | 22 | 85 | 180 | 240 | 560 | 45 | 190 | |

450 | 1450 | 750 | 1065 | 765 | 100 | 165 | 515 | 28 | 106 | 85 | 130 | 480 | 22 | 90 | 200 | 280 | 640 | 50 | 231 | |

Transmission Ratio: i=6.3~12.5 | Transmission Ratio :i=14~20 | |||||||||||||||||||

500 | 1600 | 830 | 1190 | 855 | 110 | 165 | 555 | 28 | 116 | 95 | 130 | 520 | 25 | 100 | 240 | 330 | 730 | 56 | 252 | |

560 | 1760 | 910 | 1320 | 960 | 120 | 165 | 575 | 32 | 127 | 110 | 165 | 575 | 28 | 116 | 280 | 380 | 820 | 63 | 292 | |

630 | 1980 | 1010 | 1480 | 1080 | 140 | 200 | 660 | 36 | 148 | 120 | 165 | 625 | 32 | 127 | 300 | 380 | 870 | 70 | 314 | |

710 | 2220 | 1110 | 1653 | 1210 | 160 | 240 | 740 | 40 | 169 | 140 | 200 | 700 | 36 | 148 | 340 | 450 | 990 | 80 | 355 | |

Model | c | m1 | m2 | m3 | n1 | n2 | e1 | e2 | e3 | h | Anchor bolt hole | Weight (kg) | |

d3 | n | ||||||||||||

112 | 22 | 160 | - | 180 | 43 | 85 | 75.5 | 92 | 134 | 125 | 15 | 6 | 60 |

125 | 25 | 180 | - | 200 | 45 | 100 | 77.5 | 98 | 153 | 140 | 15 | 6 | 69 |

140 | 25 | 200 | - | 210 | 47.5 | 112.5 | 85 | 106 | 171 | 160 | 15 | 6 | 105 |

160 | 32 | 225 | - | 245 | 58 | 120 | 103 | 126 | 188 | 180 | 18.5 | 6 | 155 |

180 | 32 | 250 | - | 275 | 60 | 135 | 110 | 134 | 209 | 200 | 18.5 | 6 | 185 |

200 | 40 | 280 | - | 300 | 65 | 155 | 117.5 | 148 | 238 | 225 | 24 | 6 | 260 |

224 | 40 | 310 | - | 335 | 70 | 165.5 | 137.5 | 168 | 263 | 250 | 24 | 6 | 370 |

250 | 50 | 350 | - | 380 | 80 | 190 | 145 | 184 | 293 | 280 | 28 | 6 | 527 |

280 | 50 | 380 | - | 430 | 75 | 205 | 155 | 195 | 325 | 315 | 28 | 6 | 700 |

315 | 63 | 420 | - | 490 | 78 | 223 | 173 | 219 | 364 | 355 | 35 | 6 | 845 |

355 | 63 | 475 | - | 520 | 92.5 | 252.5 | 192.5 | 238 | 398 | 400 | 35 | 6 | 1250 |

400 | 80 | 520 | - | 590 | 95 | 265 | 215 | 275 | 445 | 450 | 42 | 8 | 1750 |

450 | 80 | - | 400 | 650 | 117.5 | 317.5 | 242.5 | 305 | 505 | 500 | 42 | 8 | 2650 |

500 | 100 | - | 440 | 710 | 120 | 345 | 262.5 | 337 | 557 | 560 | 48 | 8 | 3400 |

560 | 100 | - | 490 | 790 | 120 | 390 | 265 | 354 | 624 | 630 | 48 | 8 | 4500 |

630 | 125 | - | 540 | 870 | 115 | 425 | 295 | 384 | 694 | 710 | 56 | 8 | 6800 |

710 | 125 | - | 610 | 950 | 140 | 480 | 335 | 440 | 780 | 800 | 56 | 8 | 8509 |

ZLY Hardened cylindrical Gear Reducer/Gearbox Product Display

ZLY Hardened cylindrical Gear Reducer/Gearbox Packaging