Steel casting refers to parts made of cast steel.It is better strength than cast iron

Steel Casting Product Description

Material | Carbon steel, alloy steel, stainless steel |

Process | Lost wax casting + cnc machining |

Casting dimension tolerance | CT7 |

Casting surface roughness | Ra 12.5um |

Casting weight range | 0.1-90kg |

Casting Size | Max linear size: 1200mm, Max diameter size: 600mm |

Machining Precision | Positioning accuracy 0.008mm, Rep. position. accuracy 0.006mm |

Machining surface roughness | Ra0.8~6.3um |

Max Travel Of Spindle | 1800mmx850mmx700mm |

Max Turning Diameter | 1000mm |

Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR....... |

Surface treatment | KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder coating, Nickel plating |

Service available | OEM & ODM |

Quality control | 0 defects,100% inspection before packing |

Application | Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. |

Steel Casting Processes

Confirmation Drawings - Open Tooling - Sample Approval - Incoming Qulity

Check - Investment Casting - Fix the burrs - Drilling and Threasing - CNC

Machining - Polishing - Internal Process Quality Check - Surface Treatment

- Packing - Outgoing Quality Check - Shipping

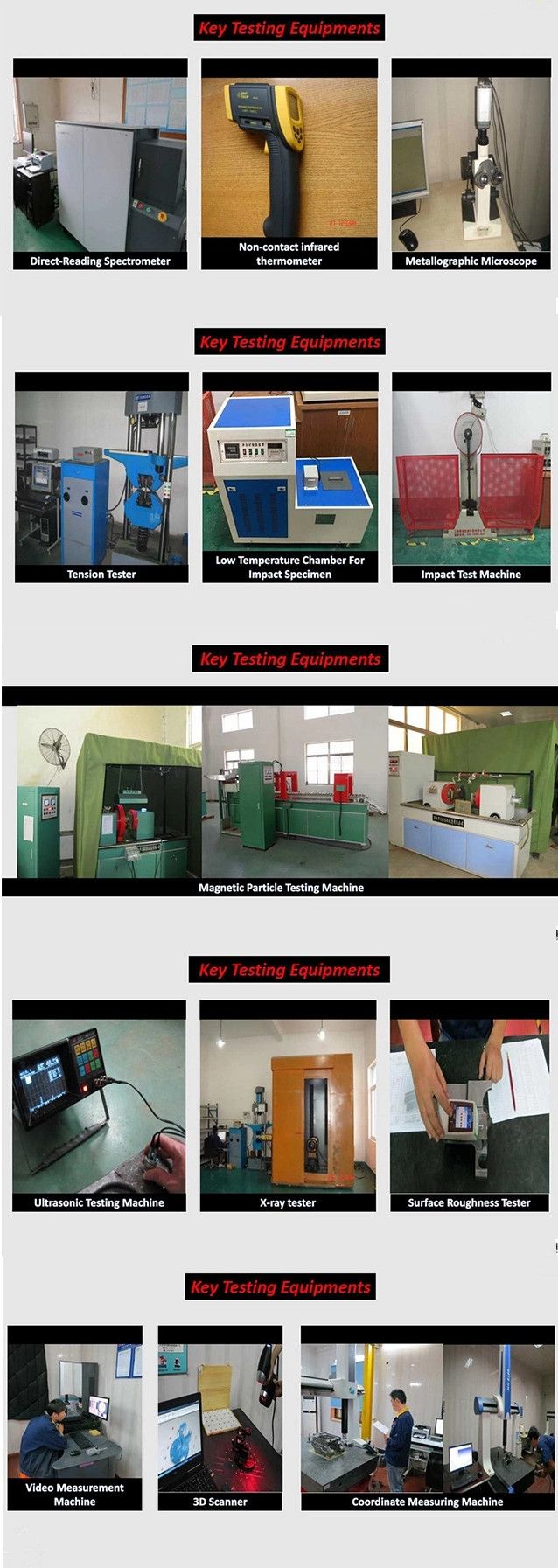

We provide various test facilities as mentioned under

1. Chemical analysis |

2. Tensile strength |

3. Elongation rate |

4. Shrinkage rate |

5. Impact test |

6. Harness test |

7. Metallography |

8.Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle and radiography) |

9. Surface roughness test |

10.CMM test |

Key Casting and Machining Equipment

Key Testing Equipment